PANEL 1

The 60s began in Italy

Italy early 60s: Between Traditional Masonry and Early Prefabricated elements

- The building activity was booming but the manpower was not qualified. The prevailing technology was therefore masonry or reinforced concrete cast in situ which allowed very large tolerances.

- Prefabrication, therefore, took its first steps with the evolution of bricks into concrete blocks thanks to true pioneers.

- The most advanced prefabricated floor of this period was the panelled one: brick blocks placed side by side with a small concrete pour in a specially created recess, where a rod was inserted acting as a beam for partial self-supporting on site. A great conceptual and technological innovation of the 1920s, yet unchanged for decades.

1962 - Born with a passion for industrialised construction

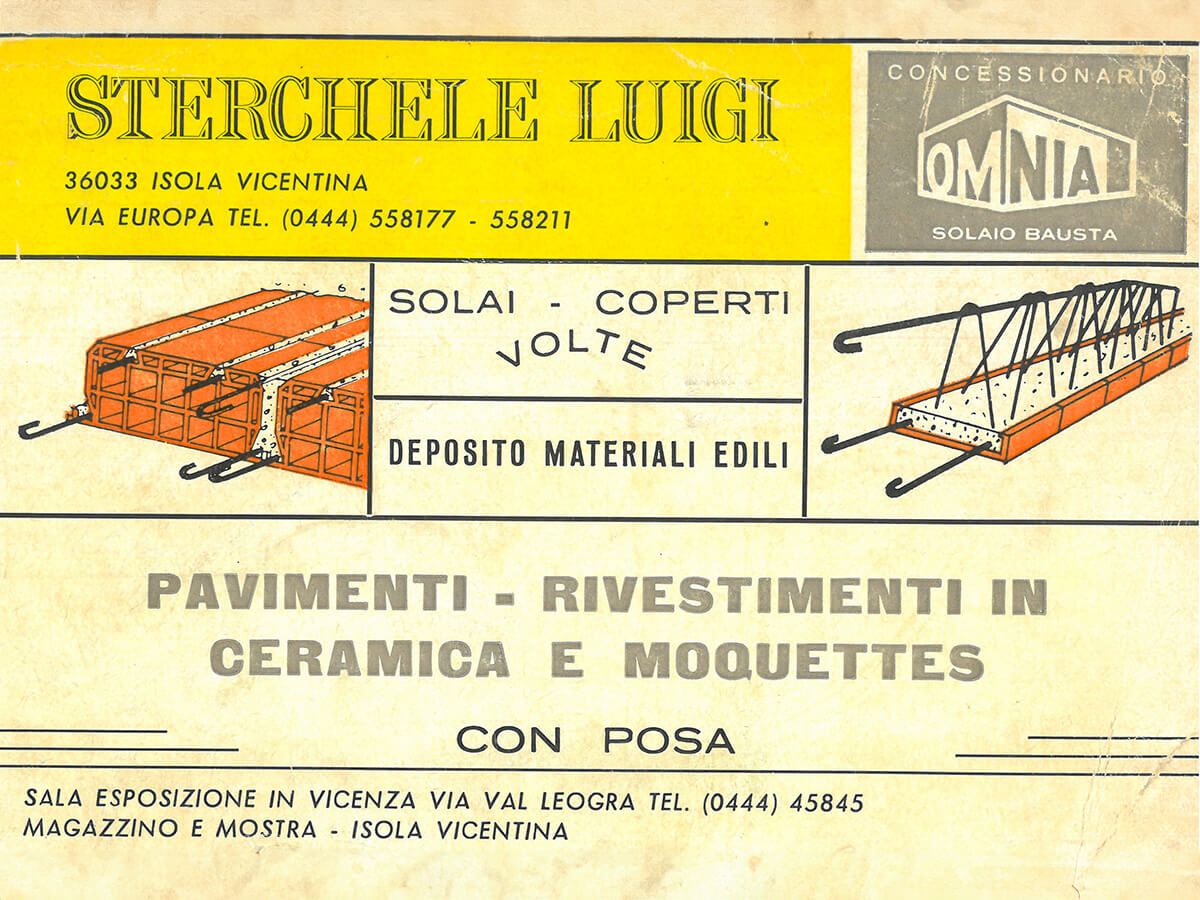

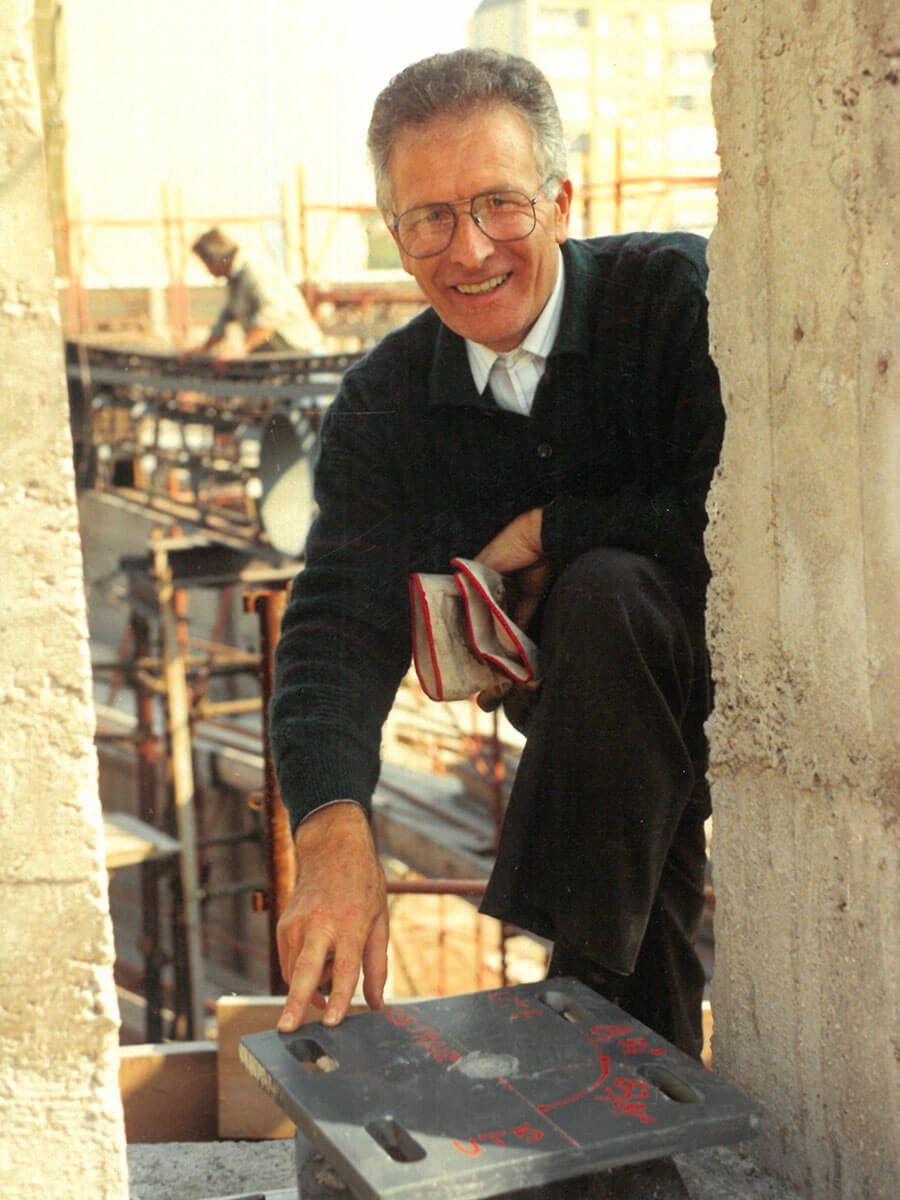

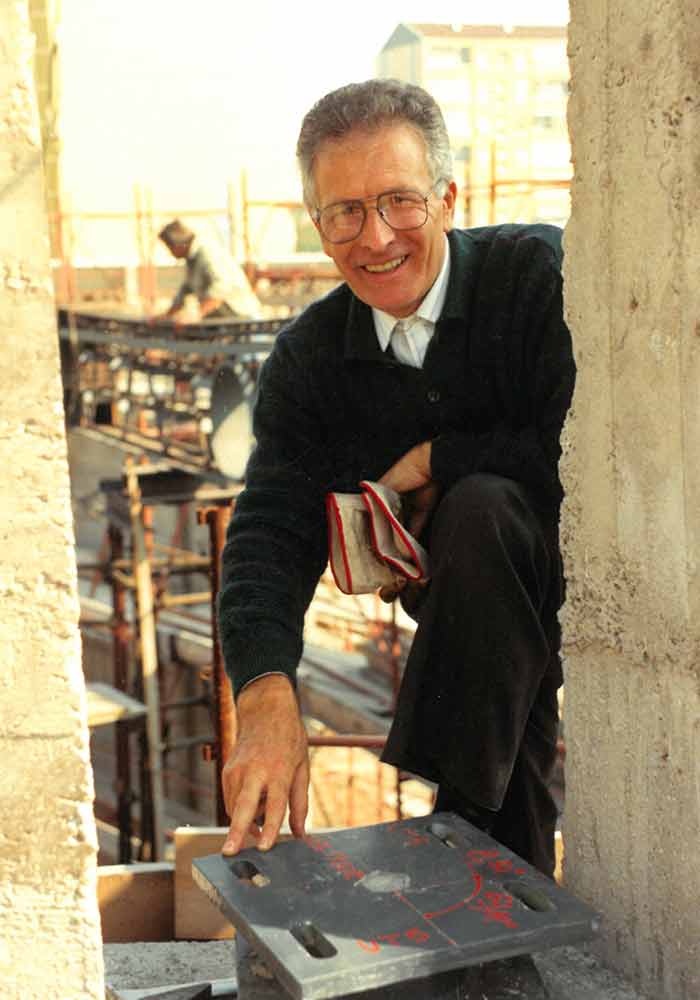

In 1962, our story began in Isola Vicentina (VI) thanks to the vision and ingenuity of Luigi Sterchele.

The firm began with the production of small construction products, including concrete blocks, but soon, with the mission of easing work on the construction site, Sterchele started a pioneering production of lattice floors, both with beams and panels. A true technological innovation for the time. The success of these products strengthened his visionary approach, starting a series of innovations in the production of prefabricated products and components.

Since then, the company has expanded and improved its production range, gradually replacing old products with new innovative ones. Continuous research and intuition have consolidated the company as a point of reference in the light prefabrication and bathroom pods market, first at regional, then national and finally European.

1962

Sterchele was born, starting the production of small prefabricated products and components and the marketing of building products and materials.

BACK TO MENUPANEL 2

1971: The Lattice Beam - a technological leap

The introduction of prefabricated beams with brick shells, welded trusses and industrial automation improved logistics and productivity

- In this climate of great creativity, Pittini imported the Bausta three-dimensional truss in Italy, which led to the birth of the new technological category of lattice floors.

- The first was the lattice beam floor with a brick base. The beam was more consistent and resistant than the panel floor, to extend the spans, but above all the lightening blocks went from the furnace to the construction site, without passing through the prefabricator, with an evident improvement in logistics and overall productivity.

- Furthermore, production went from a manual process to one largely assisted by industrial plants. Although today this technological leap may seem modest, at the time it represented a real step forward towards a more advanced industrial process.

1971

In line with our propensity for innovation, Sterchele began the production of lattice beams. This represented a significant technological leap for the time, as the introduction of the machine began to replace manual labor, marking a significant advancement in the production process.

1972

Moreover, Sterchele applied the new technology to the paneled floor, thus transforming it into a lattice floor, which enabled to integrate an upper concrete layer and extend its strength.

Last but not least, it engineered a bespoke production plant increasing the overall productivity.

PANEL 3

1975: The advancement of off-site prefabrication

- By then, prefabrication technology was striding into the market.

- In the field of industrial warehouses, innovative pre-stressed flat roofs and facade panels began to emerge, replacing the traditional brick vaults with eliminated thrust.

- In the field of civil construction, the first lattice slabs appeared with a huge leap in performance: 1) the resistant section goes from a T to a double T with a much higher rigidity; 2) the beam can be as wide and resistant as desired; the lightening quickly becomes polystyrene with a gain in its own weight and the possibility of easily managing the perforations : in short, a floor slab that is extremely more performing and ductile for many varied applications.

1976

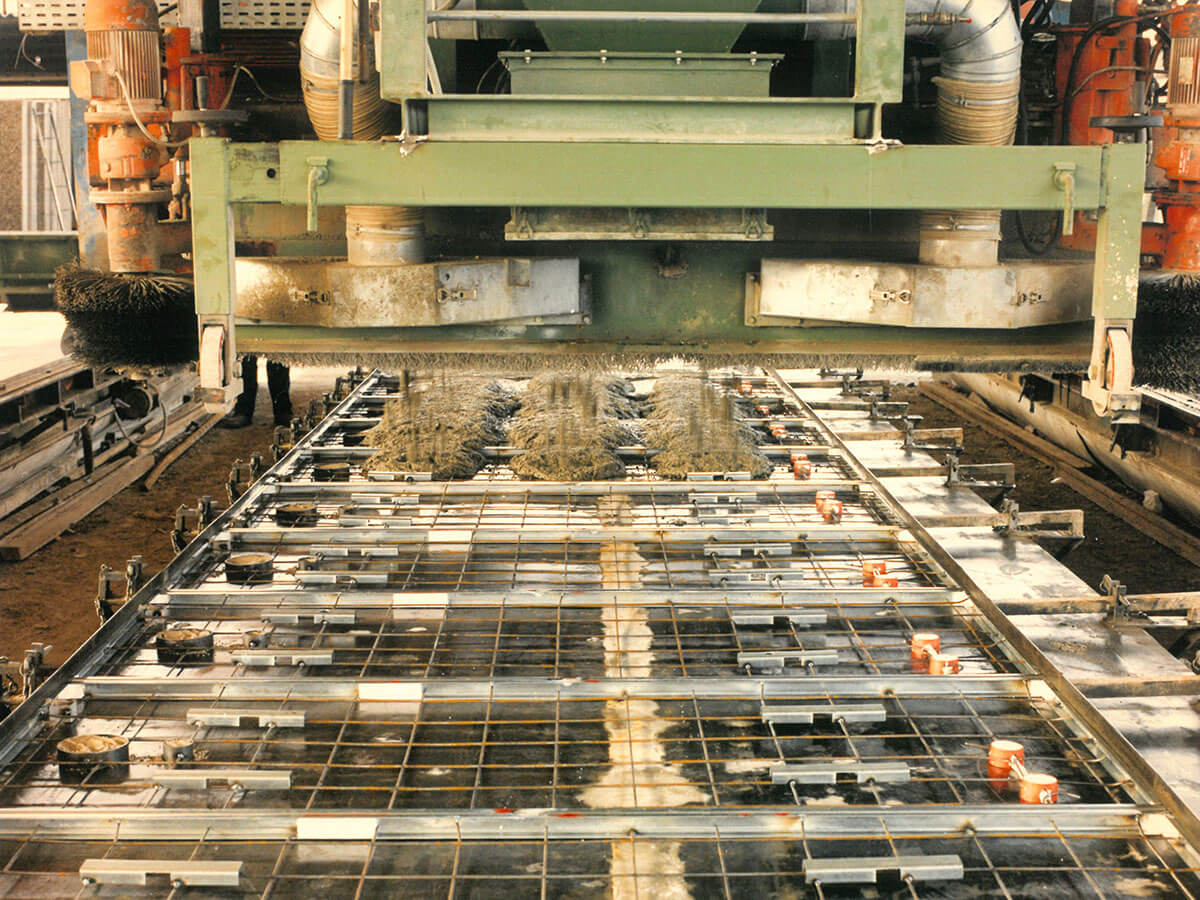

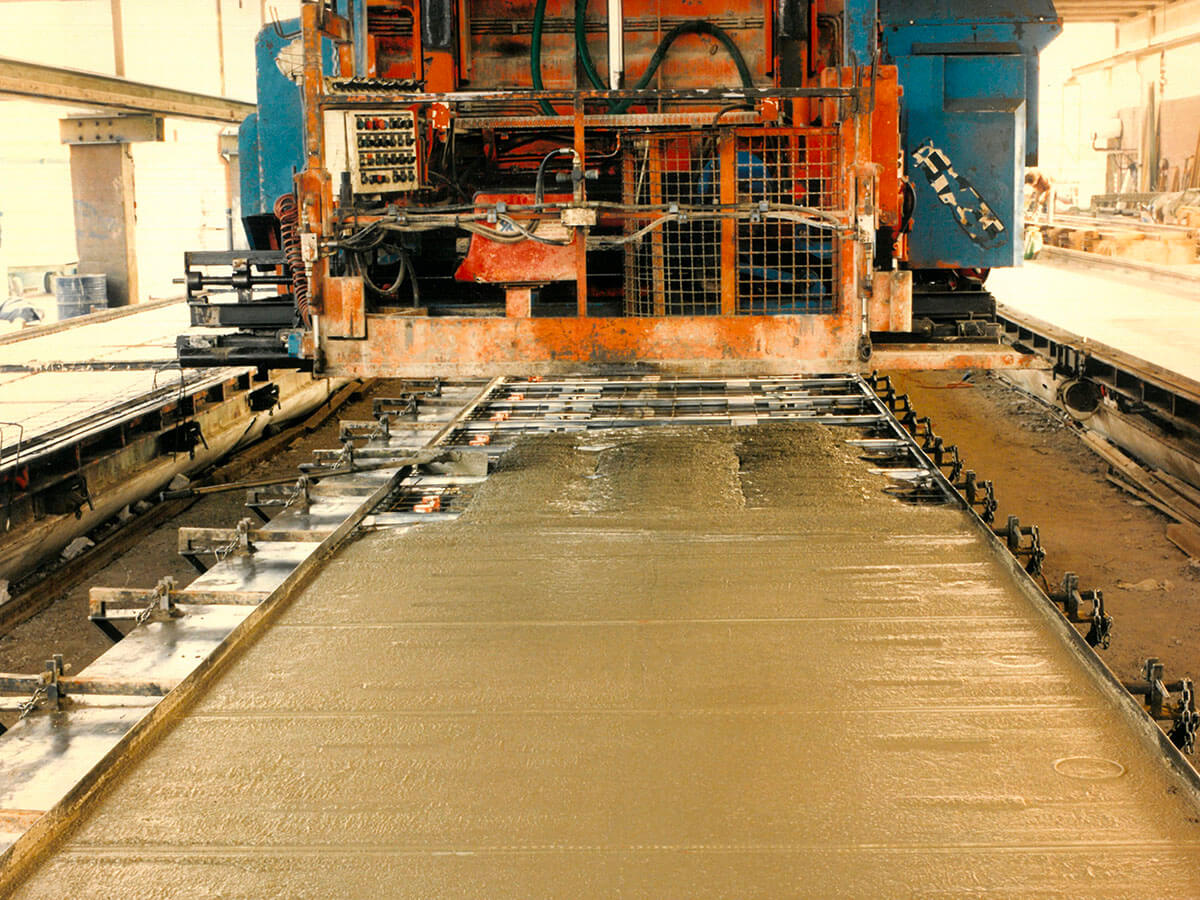

With the advent of electro-welded truss on the Italian market, we were among the pioneers in the production of Predalles slabs.

Until then, our product portfolio consisted mainly of the construction of various types of floors, reaching a quantity of 250,000/270,000 m2 per year in the 1980s.

1971-76

The first brochures

BACK TO MENUPANEL 4

1970

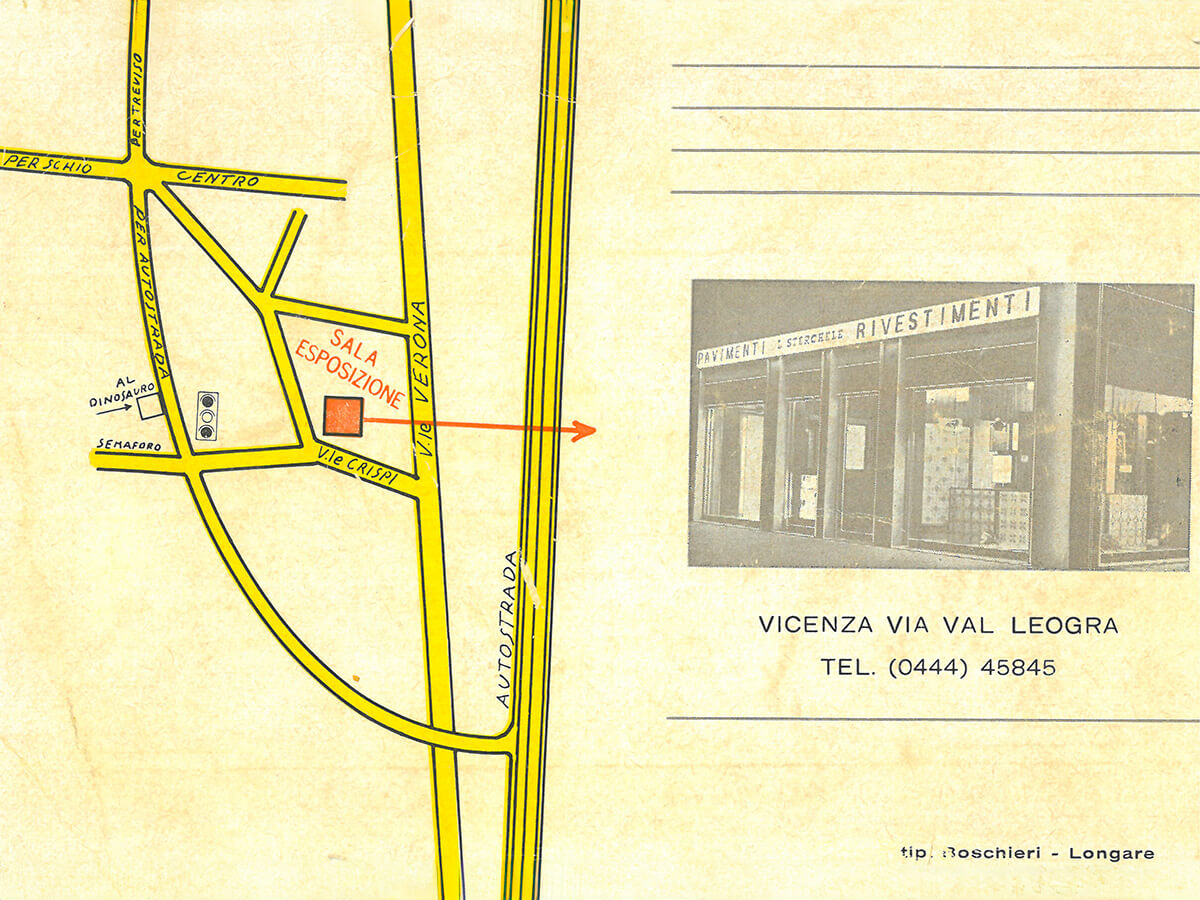

We also enter the market of building materials and coatings, starting with a small agency with a warehouse in our headquarters in Isola Vicentina.

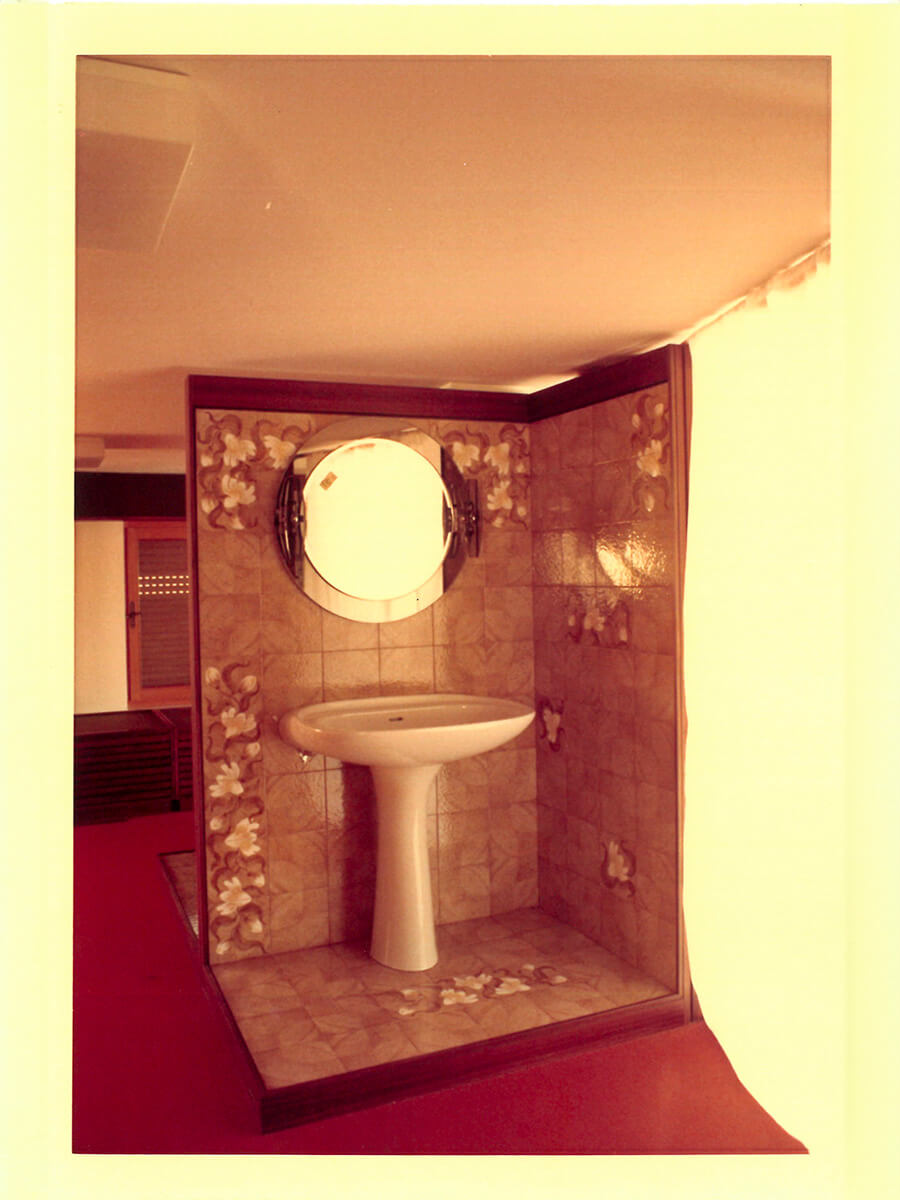

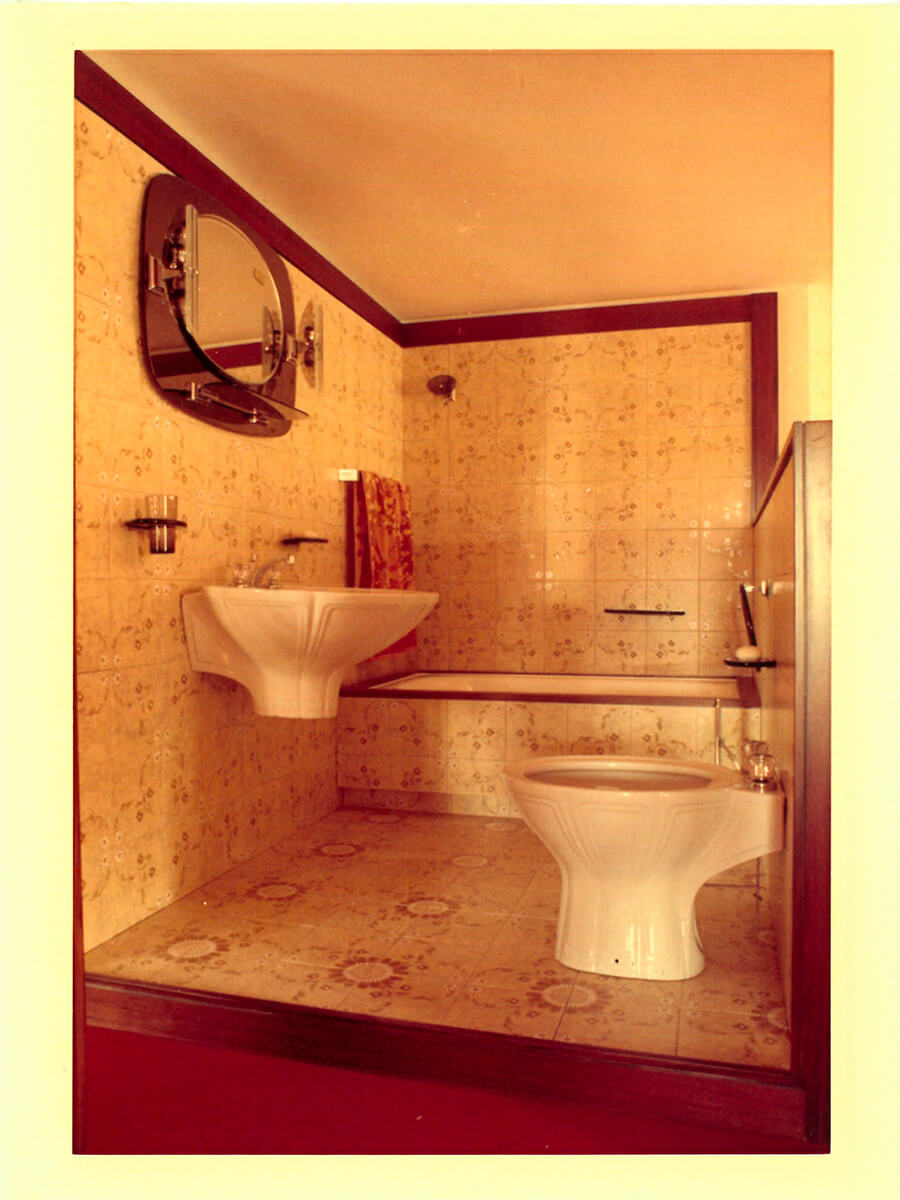

Shortly after, the Floor and Wall Covering Showroom was opened in Vicenza, starting to manage "turnkey" orders that included both the design and the complete construction.

1973

We opened a construction warehouse and showroom in Canove di Roana, on the Asiago Plateau, which remained in business until 1980.

1978-79

We identify the facade elements as a qualifying and distinctive part of prefabrication.

Opting for those that best align with our vision, that is, customized and tailor-made solutions.

This strategic choice has consolidated our brand as a leader in the sector, a role that we continue to maintain today.

1970, our first warehouse: We enter the market of building materials and coatings

It’s the early 1970s in Italy, and we are starting with a small agency with a warehouse in our headquarters in Isola Vicentina.

Browse the gallery to visit the interior of the store.

PANEL 5

Italy's ‘80s: the rising of truss beams.

The significant development of prefabricated floors had increased the demand on the construction site for the next step: prefabricating the beams, so that, once the pillars had been cast, the structure could be completed more quickly, approximately halving the installation time.

In this scenario, the Reticular Beams, later called PREM, imposed themselves, an innovative solution that combined the self-supporting nature of steel structures with the tolerances of reinforced concrete, offering a final result completely similar to casting on site.

Sterchele’s first construction system

Luigi Sterchele, recognizing the potential of PREM beams, began offering a complete flooring package, leading to the founding of I.PRE.S. (later SD Ltd.). The company developed the RET software, innovating with the use of ribbed weldable steel for PREM beams.

Once again Luigi Sterchele understood that, as a large manufacturer of floors, he could complete his range of proposals with the PREM Beams, proposing a construction system that was certainly completer and more efficient.

With a pragmatic approach, he began sourcing beams and offering customers a complete package.

The success of this formula led him, in 1981, to found I.PRE.S., later transformed into SD Ltd, which soon specialized in the design and production of PREM beams, starting an internal development program.

The company developed its own automatic calculation software, RET, exploiting the use of weldable ribbed steel for the PREM Beams, marking an important technological innovation compared to the common BEAMS of the time which used less performing and more expensive carpentry steel.

1980

In 1980, Sterchele transitioned from a sole proprietorship to a joint-stock company.

1981

I.PRE.S. is founded, which begins to market PREM beams

1984

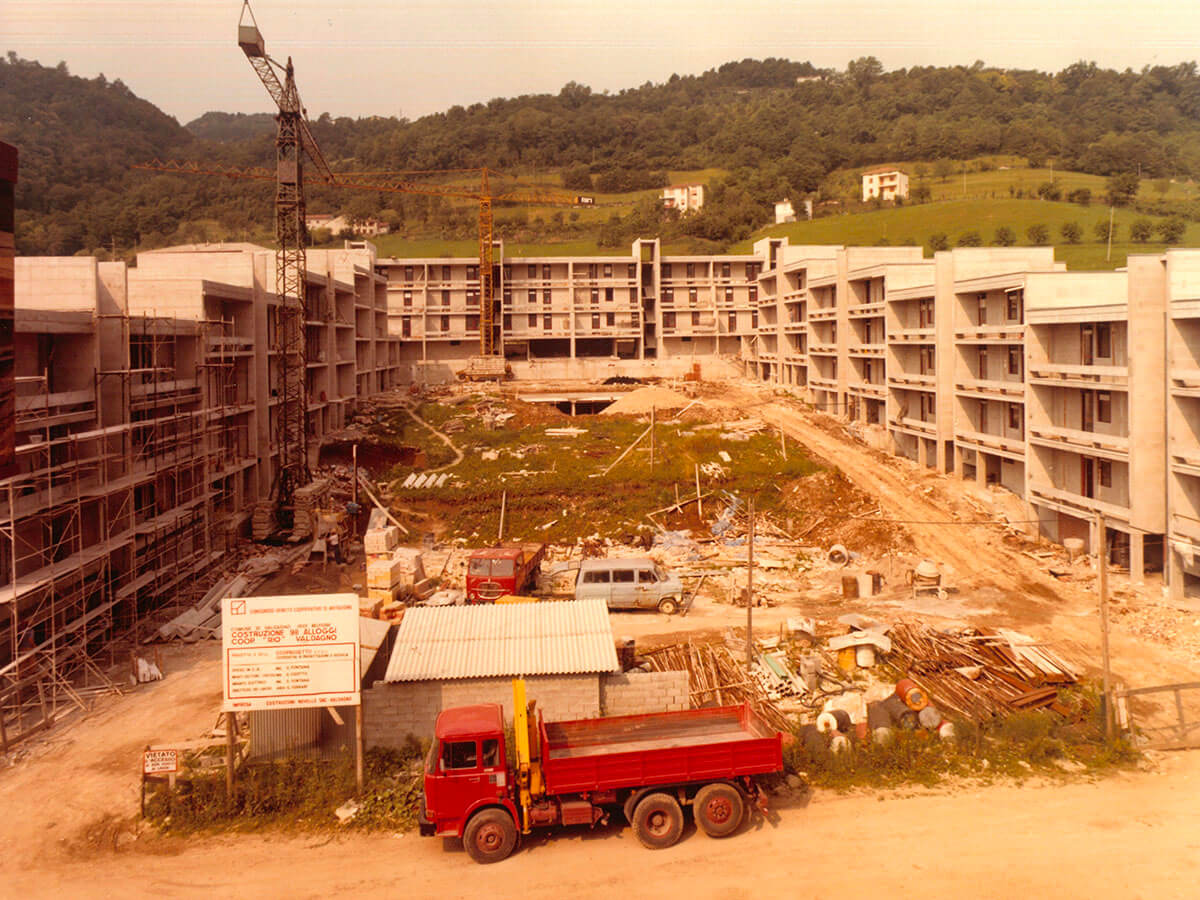

Palladium anti-seismic construction system whose concept lies in the connection between wall elements with an innovative union: fast and effective. system later evolved into the loop box connections used in the construction of prison pavilions many years later. Sterchele, once again, led the way.

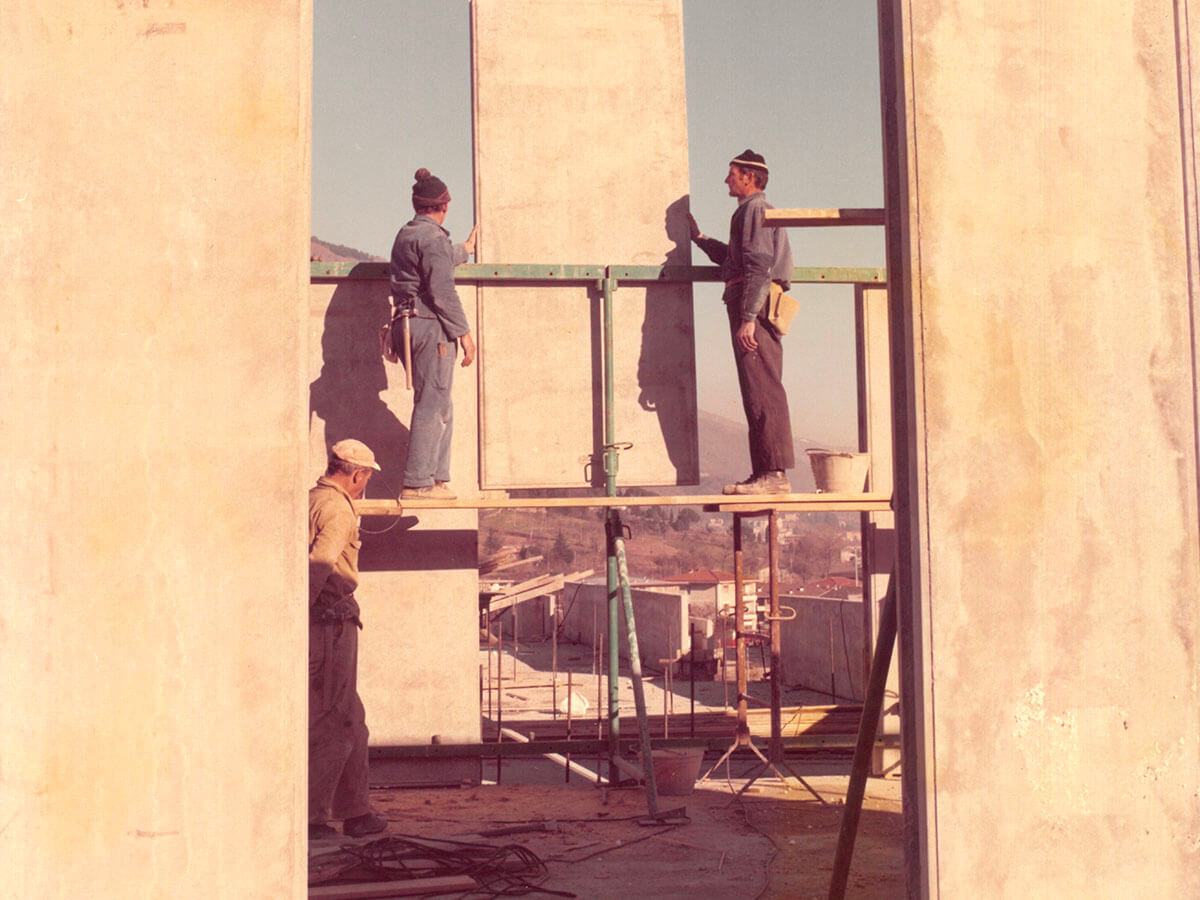

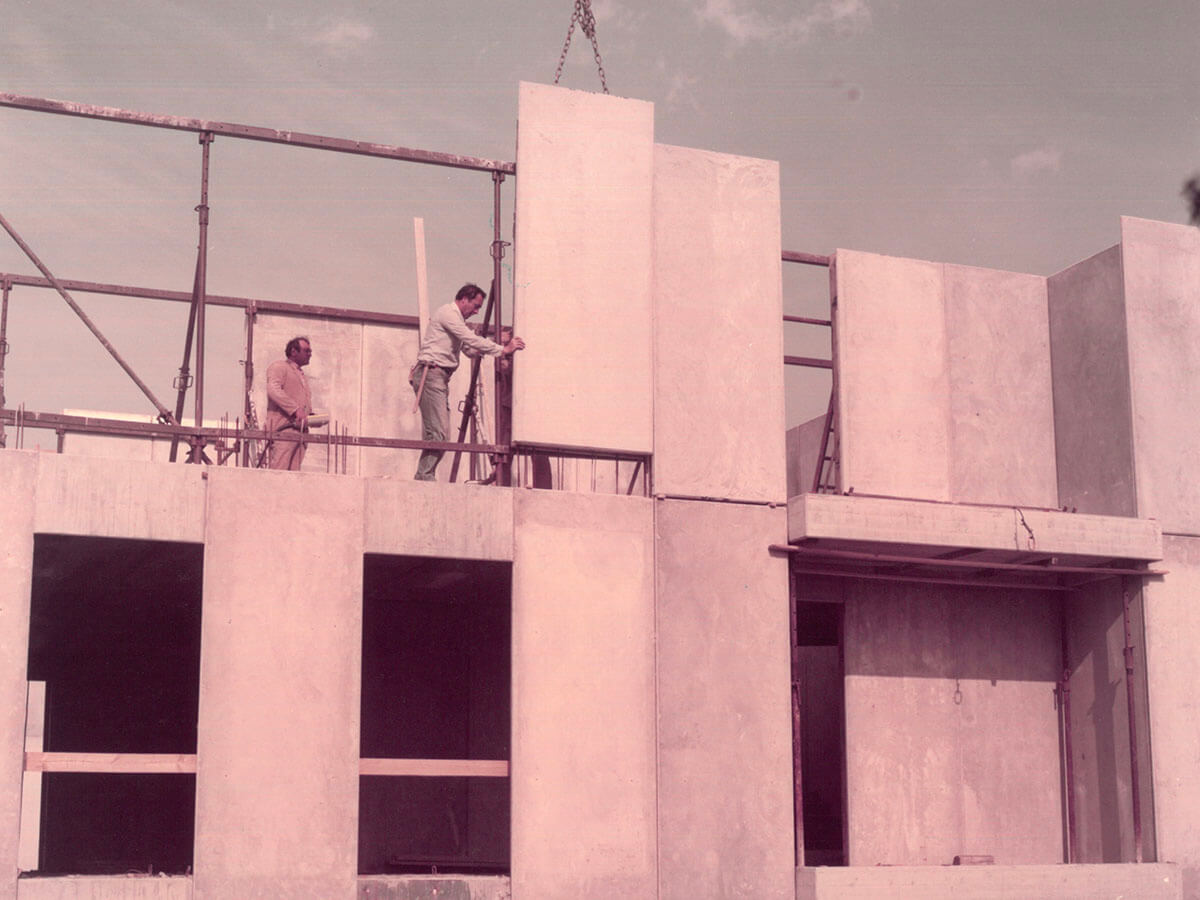

1984, we patent the Palladium System

The anti-seismic construction system Palladium is modern, fast, and effective. Sterchele pioneers and patents the system. Look at the photos and relive those moments.

BACK TO MENUPANEL 6

Subsequently, I.PRE.S. was transformed into the company SD ltd, and began its own production of beams, subsequently developing all aspects of design, calculation and construction of steel beams and structures.

1989

The complementarity of SD and Sterchele production inevitably leads to collaboration on construction sites: structures and infill panels in a single package.

The production range of infill panels is growing, first of all the panels with gravel finish for industrial sheds, soon becoming the suppliers of panels for all the prefabricators in northern Italy.

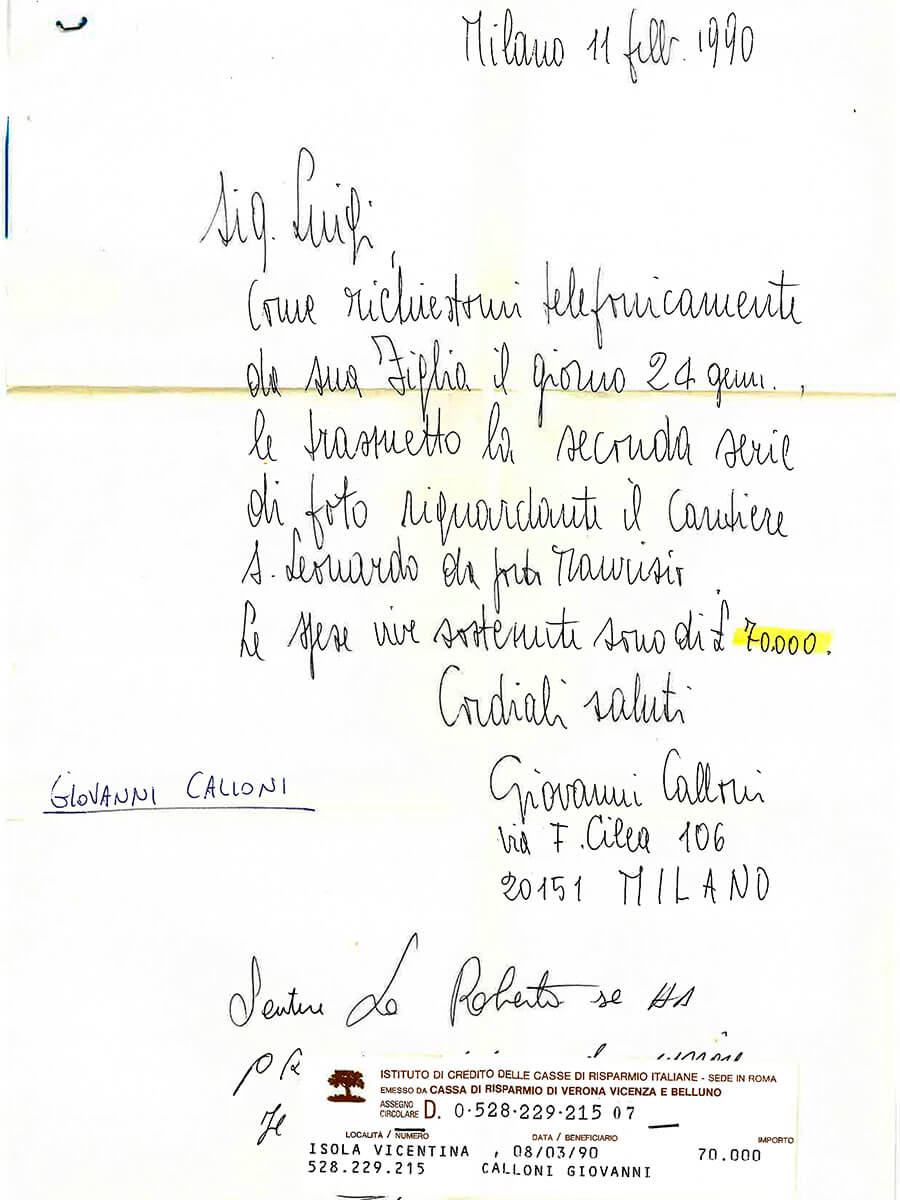

1989-1990

When Emails Were Letters and Attachments Were Photographs! / Post Offices and Films: Our Way of Communicating

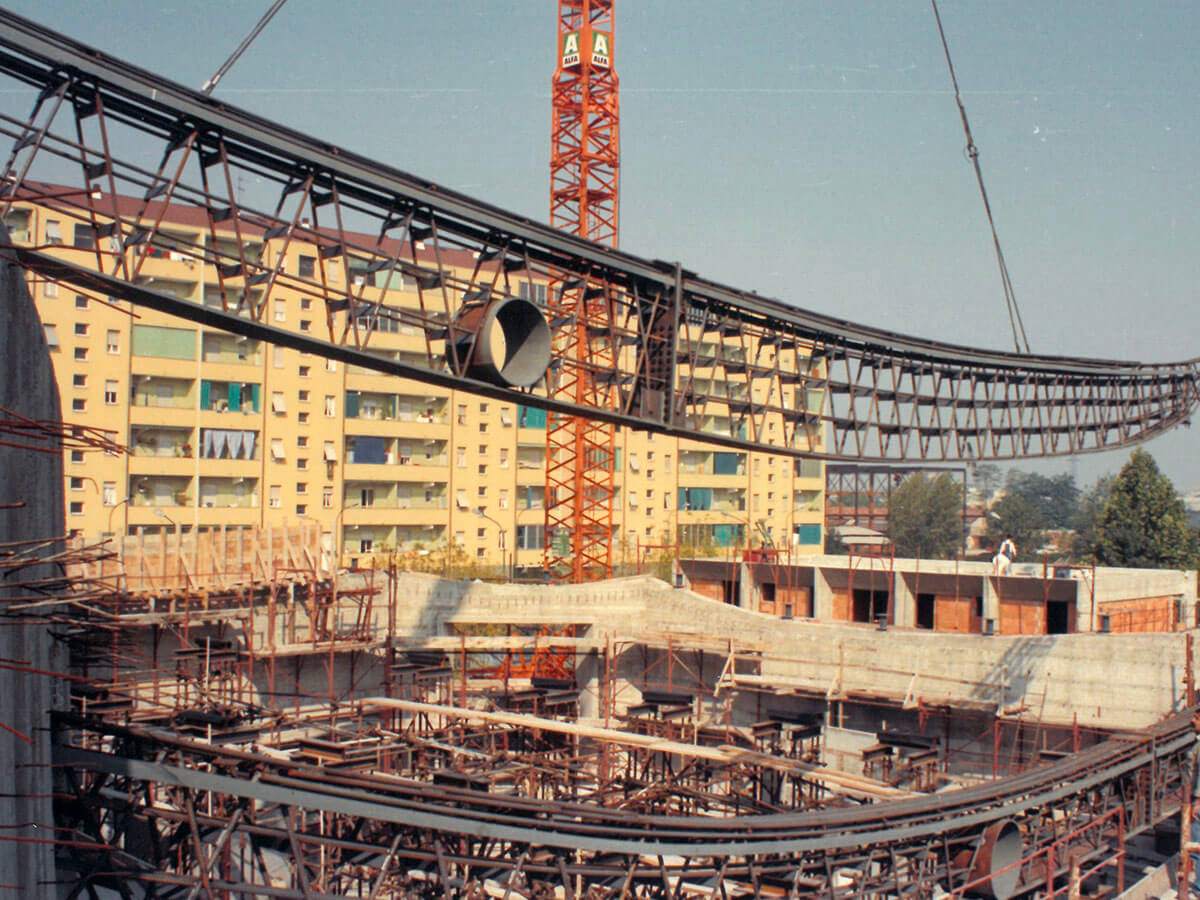

1989, the vault of the church in Pero (Milan)

It’s 1989, and Sterchele constructs the vault of the church in Pero using PREM beams on sliding supports. Look at the photos from this historic construction site.

BACK TO MENUPANEL 7

The ‘90s in Italy: Prefabrication Becomes Established

During this decade, European standards for various products are developed, and two types of Structural Wet Node columns emerge: the steel tube column and the prefabricated concrete column.

Prefabrication is now consolidated: in this decade all the harmonized European standards for the most diverse products will be developed.

These are years in which the demand for a structural system with PREM beams, complete with pillars, grows strongly and two types of Structural Wet Node pillars are developed:

1) The multi-storey tubular steel pillar , light in the installation phase, to be completed in concrete on site, with large openings between the floors to allow the continuity of the nodes and the installation of the beam stumps;

2) The fire-resistant prefabricated pillar in concrete, with interruption of the casting at the interfloor level for the continuity of the beams and the interlocking at the foot by means of special metal shoes;

Both typologies allow the designer to consider the structure as hyperstatic, with seismic nodes comparable to those of a structural organism built on site.

Sterchele and SD: two pioneers, already in Team!

SD focused on steel tube columns, leveraging its expertise in steel structures, while Sterchele pioneered prefabricated concrete columns as a leading prefab manufacturer.

It was not by chance that both types of pillars were developed and adopted in order to have the right solution for each construction site.

At the same time, the company abandoned the production of predalles, which was now consolidated and lacking in innovation.

In particular, the tubular steel pillars are developed and produced by SD, thanks to its vocation in the field of steel structures, while the prefabricated concrete pillars with Wet Node are introduced by Sterchele, which carves out its own space as a prefabricator that is always at the forefront.

With a strategic vision, we have built a synergic network of retailers throughout northern Italy.

1991

A milestone in our development: the first mockup of the combination of lightweight slab-beam supported on circular pillars, crafted at Isola Vicentina.

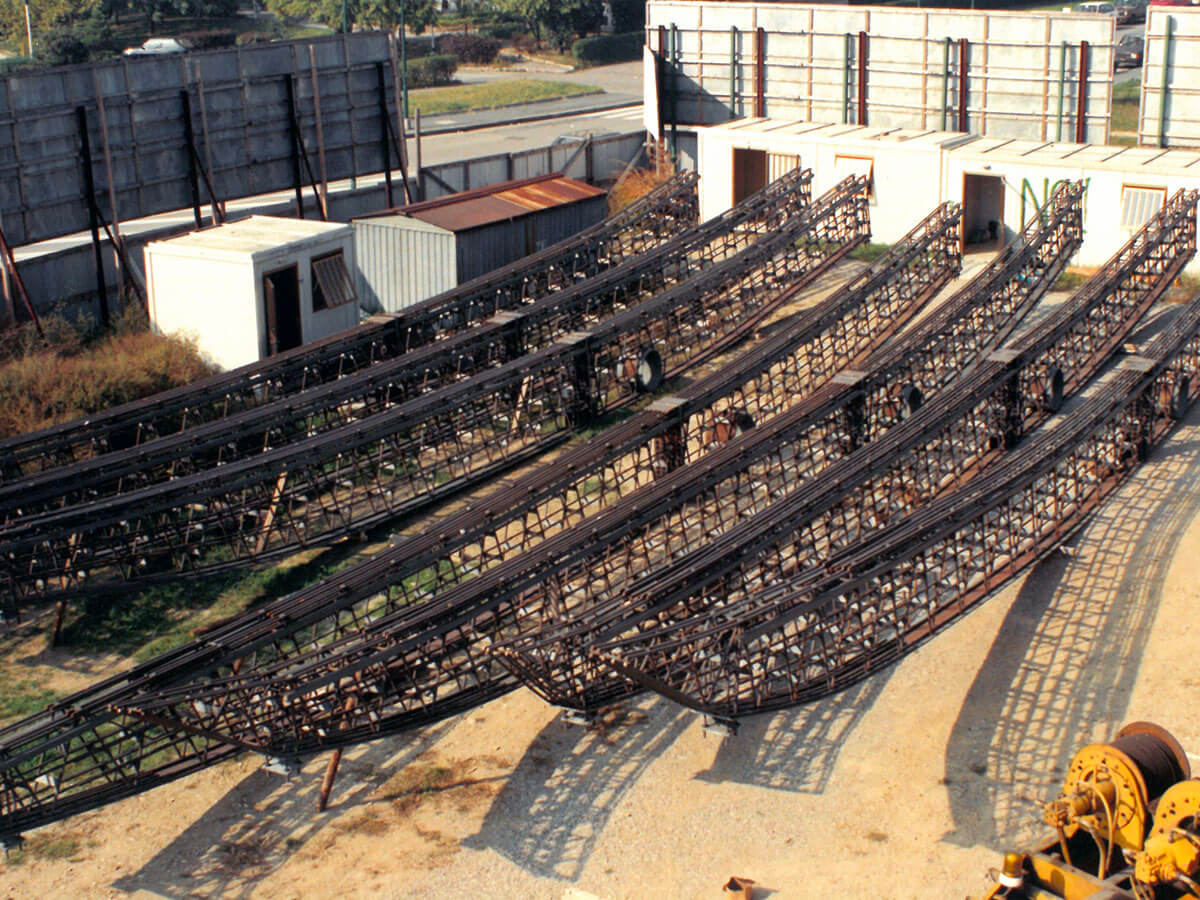

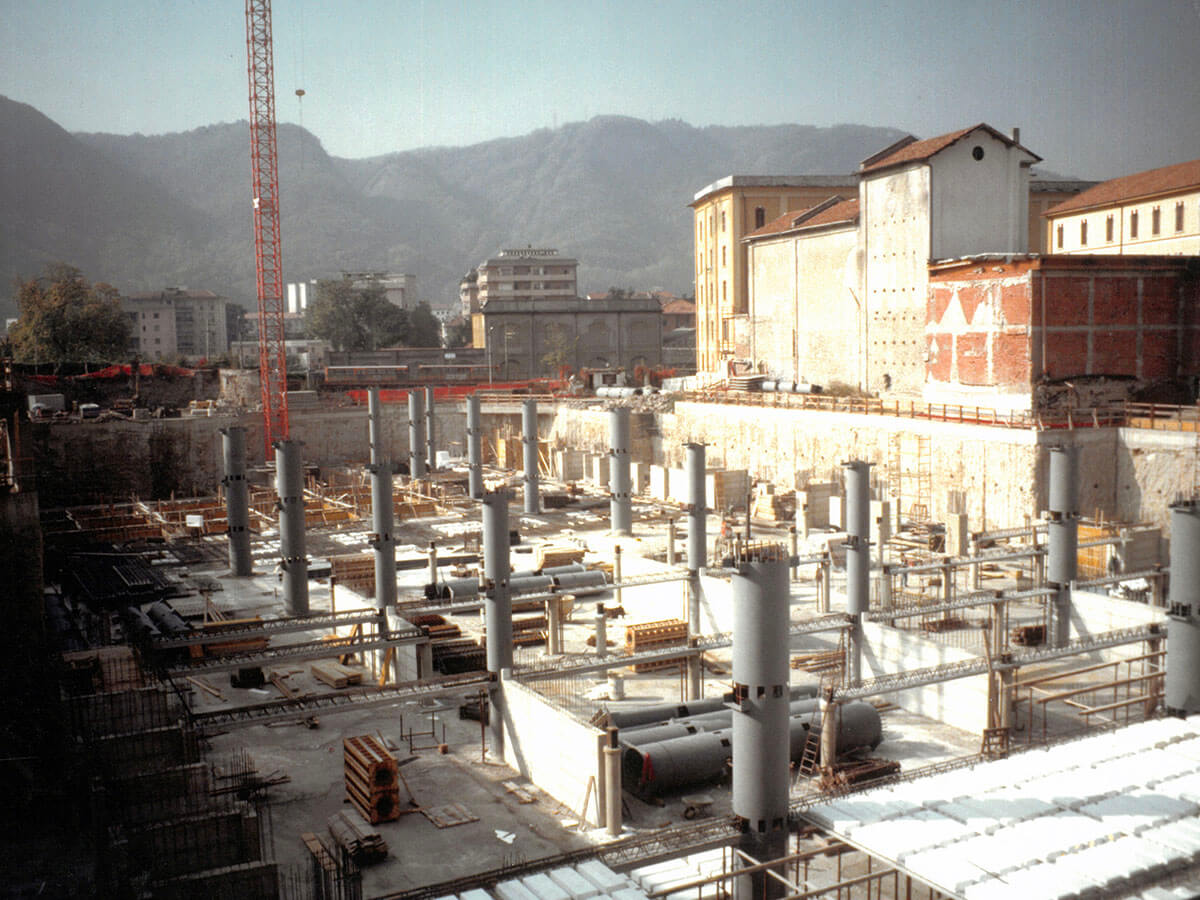

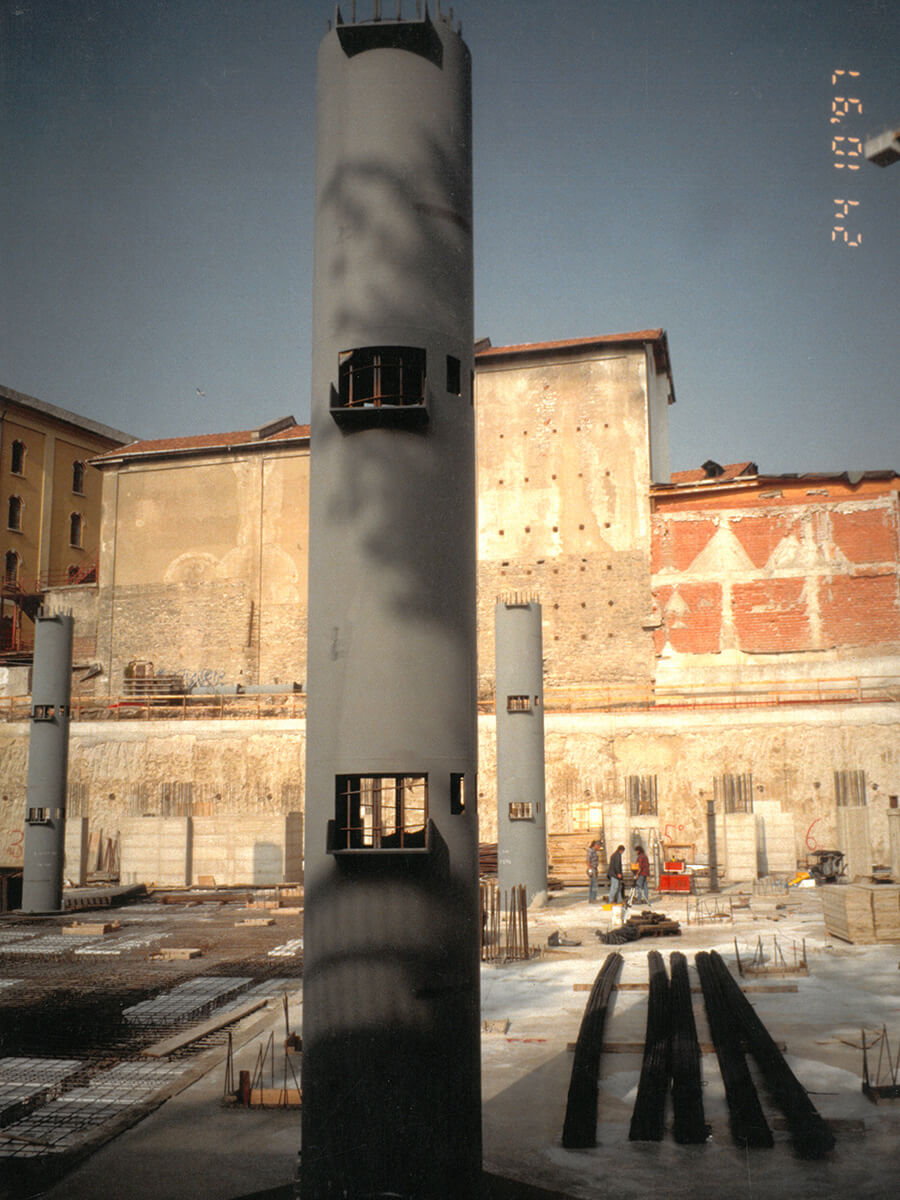

1997, the Como Borghi 2000 construction site

Como Borghi 2000 is one of the most impressive building complex built in the last decade of the 20th century in the Como valley.

It features three underground parking levels, one supermarket level, and six levels for residences and offices, surrounding two internal squares.

Browse the gallery and watch the construction video.

BACK TO MENUPANEL 8

1992

we open the construction warehouse in Olmo di Creazzo, thus expanding our resale capacity and consolidating our presence in the area.

1997

COMO BORGHI 2000: innovation and market challenge

For the first time we formalize the hyperstatic frame of the building to the market, composed of circled tubular pillars and PREM beams with concrete base. This solution represented a challenge to the sector at the time, with the production of over 2,500 tons of beams in a few months, combined with multi-storey tubular steel pillars.

Strategic agreements and key collaborations

In the same year, an exclusive agreement was signed with the company Progress for Alto Adige region, starting a collaboration that has continued for 27 years. An agreement was also signed with Generale Prefabbricati for the representation and resale of the “Spiroll” (hollow core pre-stressed) slab in the provinces of Vicenza, Verona, Padua and Venice.

2003

VOLKSWAGEN MANDOLINI AUTO DEALER – BRESCIA

One of the first construction sites where we supplied a complete package of PREM beams and hollow core slab.

EUROPA SHOPPING CENTER IN GENOA

First multi-storey precast columns in prestressed reinforced concrete ( cav ), designed using HSH Straus FEM software.

PANEL 9

The beginning and development of Bathroom Pods in Italy and Europe

In the 1990s, Construction industrialization in Italy and Europe becomes a key concept, leading to the development of Prefabricated Bathroom Pods

The industrialization of the building site becomes a key concept, favoring the development of systems and products, both structural and non- structural, with objectives oriented towards the European market.

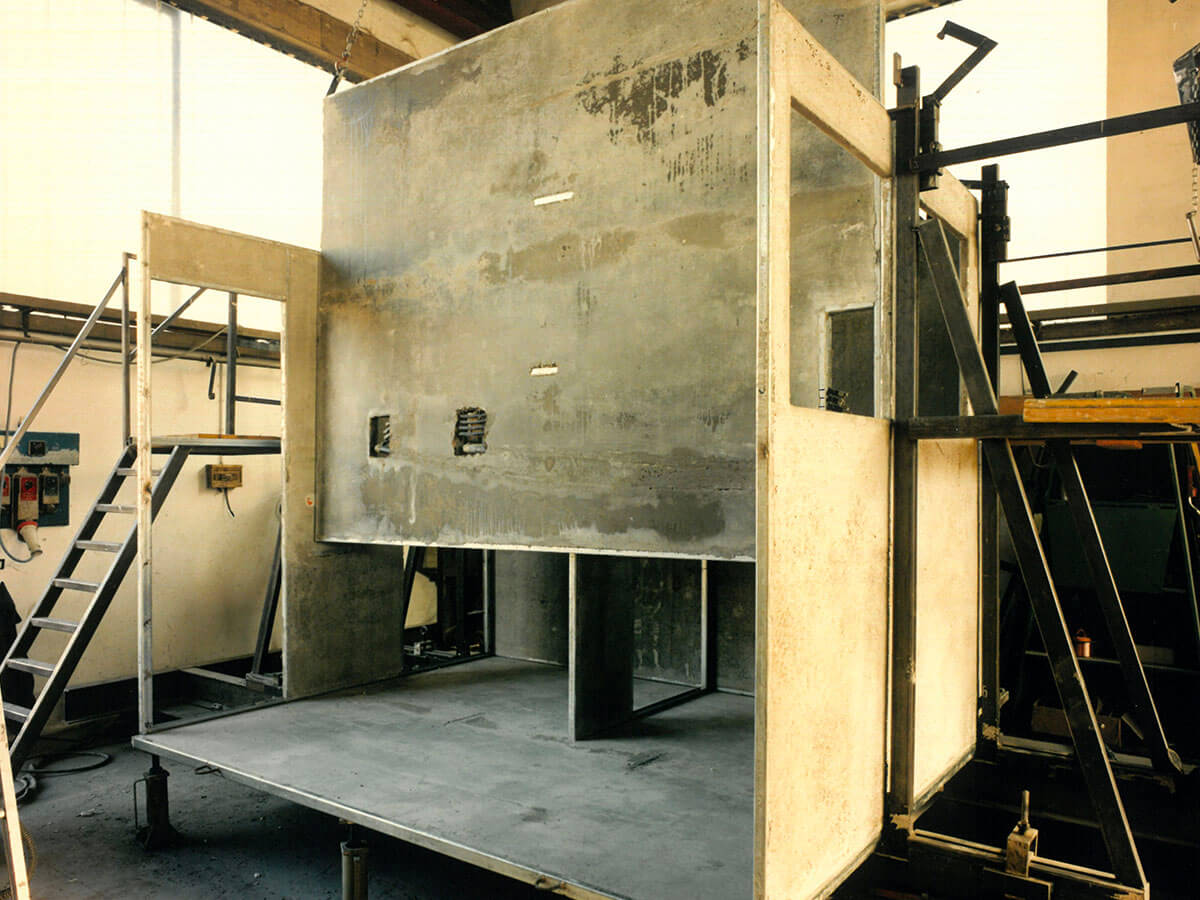

This is how the technology of Prefabricated Bathroom Pods was born, initially made of concrete and subsequently evolved into lightweight versions with a structure in steel profiles and plasterboard walls, or, with more advanced materials, in gypsum fibre boards.

The idea promises to be very effective in the field of collective residential facilities such as hotels, hospitals, nursing homes, prisons, student residences, etc.

Sterchele and the New Market Frontier

Sterchele capitalized on the burgeoning bathroom pods technology, using its expertise in prefabrication and steel processing to become a market leader, expanding its reach into Central and Northern Europe

It was inevitable that Sterchele would immerse itself completely in the new technological challenge, given the prospect of a vast and qualified market, at both the national and European levels.

The company leverages its experience in prefabrication, steel processing, purchasing of building products and assembly on site, quickly acquiring a leadership position in the sector.

Sterchele began to design and produce “light” Pods, extending its influence in central and northern Europe, where the market was more mature and receptive.

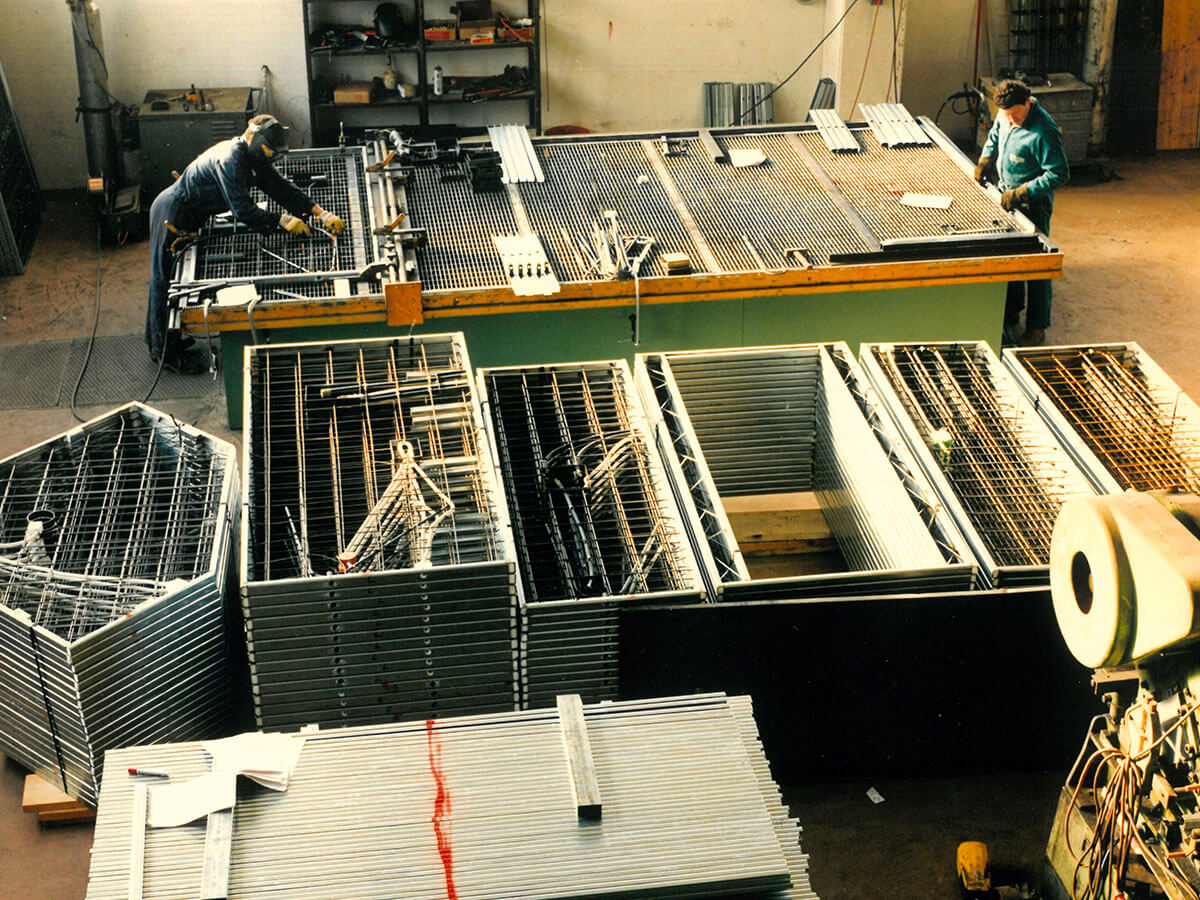

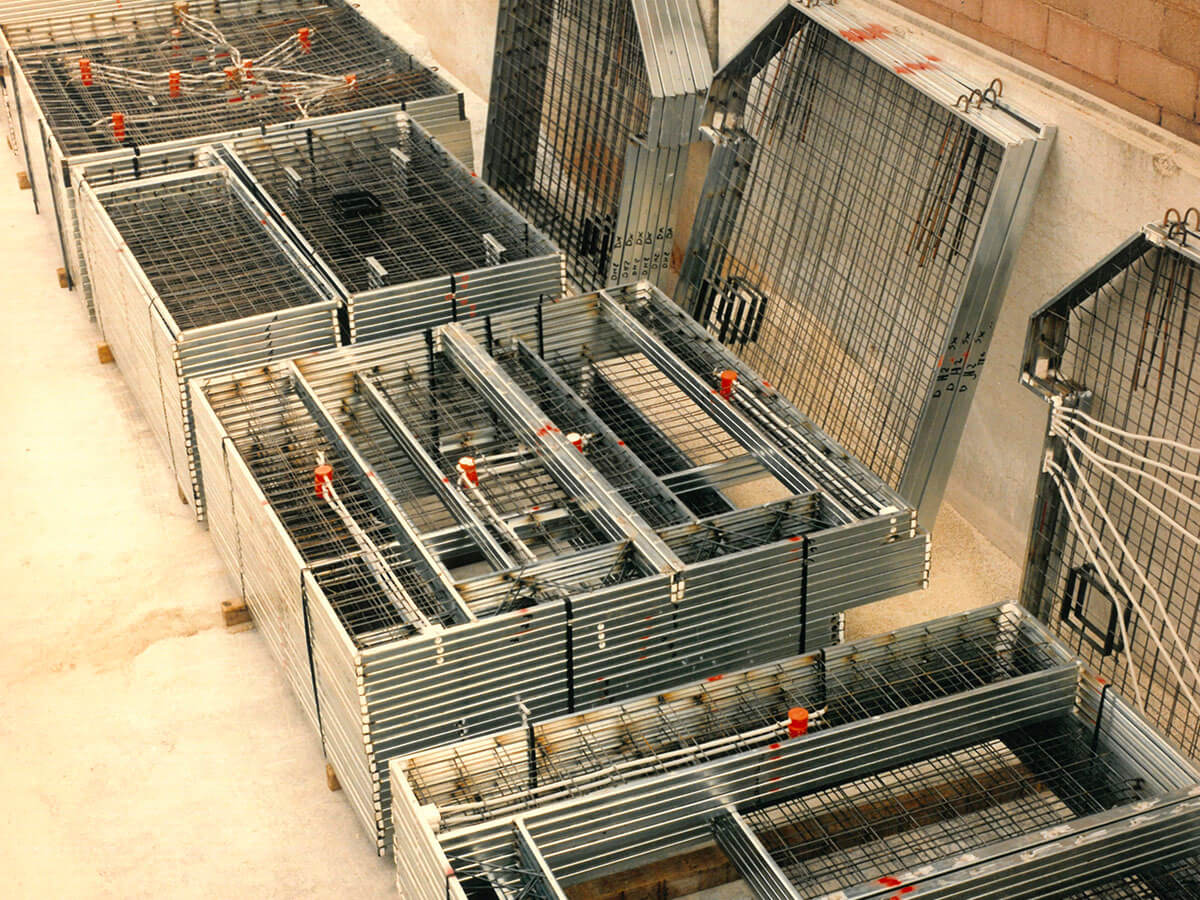

1993

FIRST BATHROOM POD

Pioneers in Italy in the Production of Prefabricated Bathroom Pods

1993

FIRST BATHROOM PODS FACTORY IN VICENZA

(from 1993 to 2002)

1993

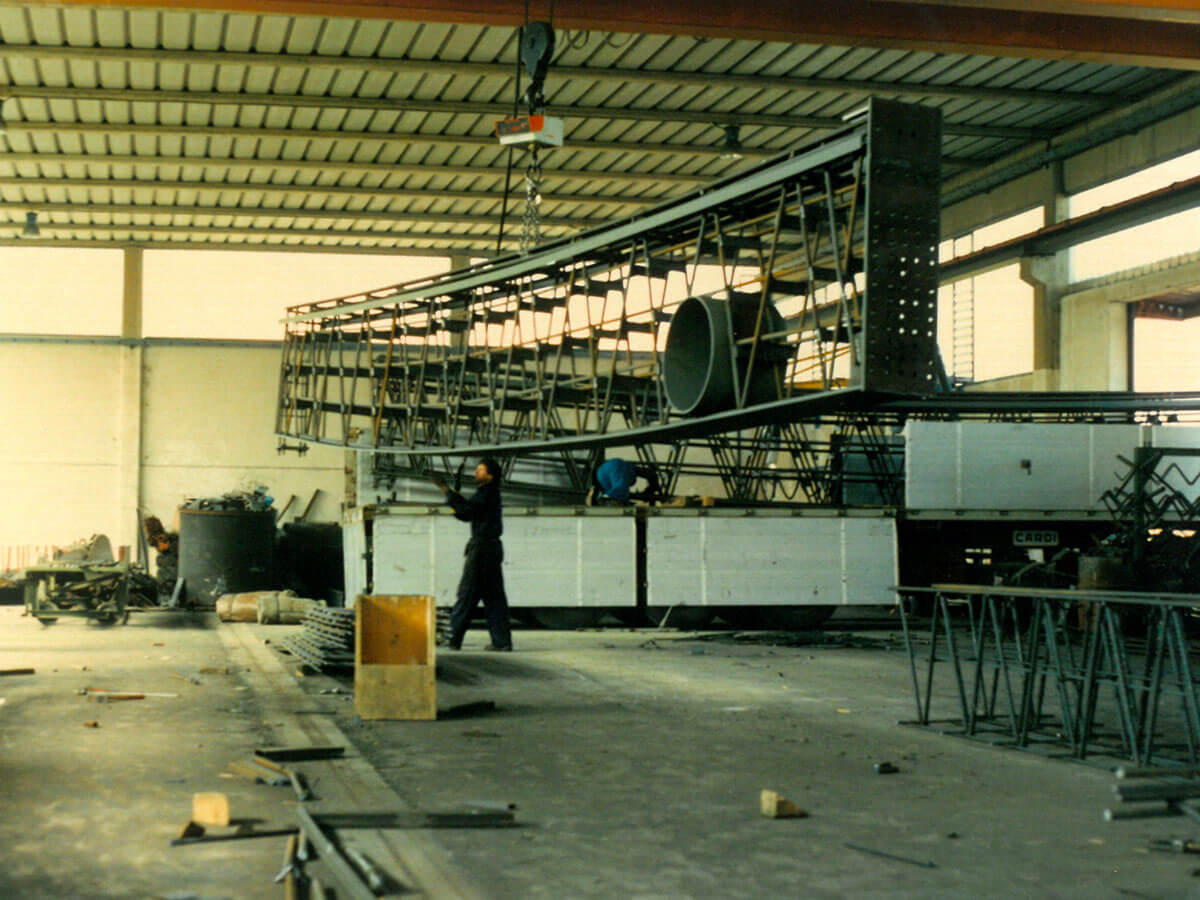

the first factory of Sterchele Bathroom Pods

The production of bathroom pods begins in a factory in Vicenza.

The frame production took place at our headquarters in Cavazzale, the casting in Isola Vicentina, and the assembly in Vicenza.

Browse the gallery.

BACK TO MENUPANEL 10

1994

Our first international project

Our first international project is a nursing home, the Nursing Home in Elstree, UK, ordered by Thomas Weatheralds Ltd.

1996

Hilton Belfast (UK)

1998

Safilo Headquarters

BACK TO MENUPANEL 11

The 2000s were happening in Italy

Founding of Assoprem, National Association of PREM Beam Producers, Development of first Design Recommendations and CSLP Guidelines for PREM Beams

- Assoprem, the National Association of PREM Beam Manufacturers, was born In 2006, and developed two large national research projects, with nine universitary research institutes and a private one, to deepen the knowledge and refine the technology of PREM Beams.

- A national working group was formed, coordinated by Prof. Giovanni Plizzari, to draft the first technical "Recommendations" and to publish the Technical Operational Guide for Professionals with all the knowledge available in the literature on this topic.

- Following this strong technical "push", the CSLP Guidelines on lattice beams were issued, identifying for the first time three distinct categories of PREM beams: in concrete, in mixed structure and hybrid.

We Couldn't Miss Out!

SD and Sterchele joined Assoprem, playing a key role in research and technical documentation. They were the first to gain recognition for producing both concrete and hybrid PREM beams and later took on the presidency of Assoprem.

- Initially, SD, recognized as the 1st manufacturer of PREM Beams with a production capacity of 3,500,000 kg/year, and subsequently also Sterchele, became part of Assoprem, actively contributing to all research activities and the drafting of technical documents.

- We were the first ever to obtain recognition from the Superior Council of Public Works for the production of both PREM beams in reinforced concrete and mixed steel-reinforced concrete beams.

- Our continuous support to Assoprem has allowed us, over time, to also assume the Presidency of the association.

- Through Assoprem, we became part of FederBeton, the main body of Confindustria that represents the entire concrete and prefabricated supply chain, to which we provided our contribution for the organization and management of various events.

PANEL 12

2001

Opening of the new store of flooring and bathroom furnishings in Creazzo

2002

Bathroom Pods production is relocated from Vicenza to the Marano Vicentino premises, optimizing our operations and improving production efficiency.

2006

After much collaboration between the two companies… also some sane “competition”

(FOOTBALL MATCH Sterchele-SD)

2006, competition ignites between Sterchele and S.D.

A match that remains in the history of the two companies before and of Sterchele Group today.

Browse the gallery below to discover the teams and take a dive into the past.

PANEL 13

The Evolution of the 2010s: Seismic Adaptations, Market Crisis, and Communication Revolution

- The 2003 Anti-Seismic Ordinance unfolds its effects with the NTC 2008 and 2018. Italy becomes entirely seismic and all structural engineers become experts in FEM modeling.

- Previous investments are coming to maturity on a technical and technological level, but since 2012 the market has had to go through a very serious crisis that will lead to a reduction of the demand first, and then of the supply.

- Those who manage to resist must optimize their organization and promote themselves better on the market.

- Communication therefore enters fully into the world of construction and tends to grow in content and technology.

- Old paper brochures and old static websites are giving way to dynamic websites, newsletters and social networks (Internet 2.0).

2006

First lightweight bathroom pod

2010

Voghera Prison Project: integration of PREM System, partition panels, and bathroom pods

Construction of the Voghera prison: integrated project of PREM system, infill panels, stairways and landings and bathroom pods

The mission of pursuing the highest possible industrialization on site has led us to propose synergic solutions, not limiting ourselves to a simple supply of single products, but creating a true integration between systems.

Thanks to the self-supporting PREM system and the use of the hollow core slab, it is possible to lay the bathroom pods directly on the floor, poured a few days before, using the same means for lifting. This approach allows to significantly reduce the installation time of the pods, usually installed at the end of the construction site via side platforms and rolling.

2013

One of the first in Italy to develop a load-bearing panel construction system

We are among the first in Italy to create a construction system with load-bearing panels, developed on loop box connections, in direct continuity with the concept of the Palladium System patented over twenty years earlier by Luigi Sterchele. Because of the effectiveness of this construction system we were appointed for the design and construction of numerous prison pavilions throughout Italy, in Trapani, Parma, Vicenza, Lecce and Taranto.

We make our entry into the Swedish market with MALMÖ LIVE project

BACK TO MENUPANEL 14

2014

StercheleGroup, the partnership between Sterchele plc and SD ltd, is now born and introduces new perspectives for the synergies that are now very developed.

A new digital structure and a renewed image are launched: the company logos are updated and the message is simplified to present the Group as a single interlocutor.

Three new websites are developed, no longer focused on individual companies, but centered on products, services and Building Systems.

Start communicating with Newsletter and Social.

First to obtain from the Superior Council of Public Works the double classification in the categories admitted by the Central Technical System (STC).

2015

The proposal of "Integrated Solutions" that combine construction systems and bathroom pods is formalized to the market, based on the consolidated global expertise, developed in the industrialization of the building site

We co-founded www.progettoprem.info , the first independent blog in Italy specialized in the technology of the PREM System

BOVIERAN

The first of 14 Bovieran projects in Sweden in collaboration with Skanska, the main contractor on the framework project.

Since then, Sterchelegroup supplied 715 bathroom pods in 14 different Bovieran projects in Sweden.

2018

Our construction system is integrated with Seismic Isolators and shock transmitters (Sant'Andrea Hospital in Rome – PREM system with Seismic Isolators; Sigonella NATO Base – PREM system with shock transmitters.

2019, NOKIA Arena

An important sports and entertainment center in Tampere, Finland. Designed to redefine the architectural standards of sports venues, it combines leisure functions, services, residences, and a Lapland Hotel. Sterchele manufactures and installs 274 bathroom pods for the hotel rooms, featuring high-end finishes and saunas.

BACK TO MENUPANEL 15

The 2020s: Embracing Organizational, Technological, and Digital Advancements

- The market has now restarted but companies have learnt from the difficulties and identify the soft aspects of the company as priorities: organization, technology and IT, to increase competitiveness and resilience in line with the spirit of Industry 4.0.

- Competition in digital communication is now very strong. It is no longer enough to be there and inform; the market also requires inspiring and dreaming, through images and engaging content.

- Environmental issues emerge forcefully and become a must in communication at all levels.

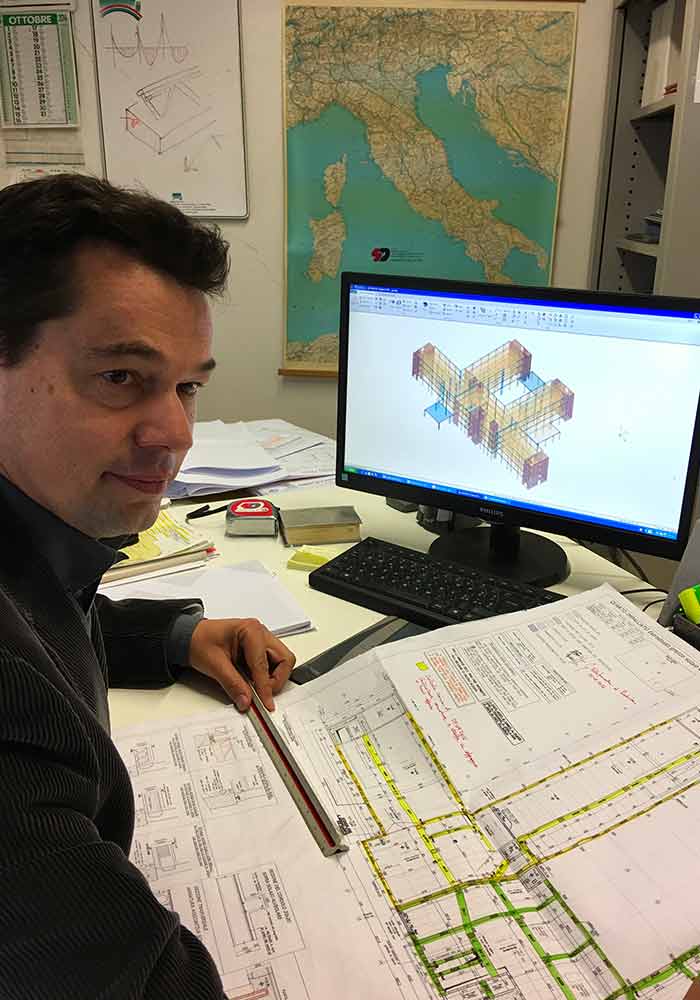

- BIM (Building Information Modeling ) is becoming a mandatory requirement in public contracts and a preferred element in large projects.

Evolution and Innovation: Our Strategic Reorganization and New Corporate Vision

Our company is undergoing a major reorganization, including a new ERP system, integrated CRM, CNC profiling machine, and BIM implementation. We are also establishing STEDIL, consolidating offices, and updating our brand image with new logos and specialized websites.

Our company faces this period of great evolution with a far-sighted vision, initiating a reorganization that permeates every aspect of the internal structure:

- A new and more efficient ERP system which integrates a new CRM program that communicates with accounts, sales and marketing;

- A new internal CNC profiling machine;

- The first BIM implementation project;

- The birth of STEDIL and the grouping of offices in a new structure;

- A new image and new logos, both for companies and for Products/Systems and 5 new specialized websites.

2022

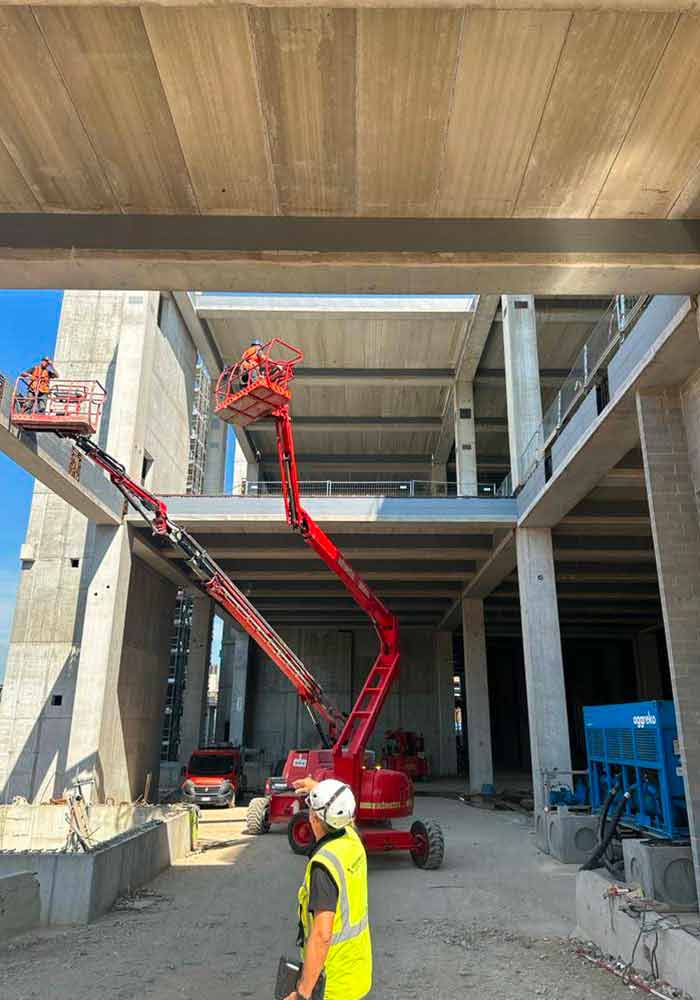

MEMC

29,000 m2 of self-supporting dry-laid floors

2023

Stedil, a long standing manufacturer and exclusive supplier of PREM beam trusses and other structural metal components, also joins the group.

2022, MEMC

MEMC Electronic Material S.p.A. is the largest producer of silicon wafers in the entire EU. The company chooses Sterchele Group for the expansion of its production facility in Novara, with a new establishment of 29,000 square meters

This is one of the largest construction sites carried out in Italy using the Structural Wet Node Prefabricated System; a challenging project, for which we leveraged all our experience to develop innovative solutions tailored to project requirements.

BACK TO MENUPANEL 16

2024

We are starting a new chapter with the rebranding and launch of our new corporate websites to consolidate our evolution and commitment to the sector by projecting us towards new developments

Study, research, constant commitment, critical sense, courage, resourcefulness and enthusiasm have been, since 1962, the basis of the spirit of our company, together with a strong drive for innovation supported by a curiosity for everything that surrounds us.

Today, thanks to our long experience, consolidated technical expertise and the synergic spirit of our Team, we create cutting-edge products and solutions with the sole and essential goal of offering each individual customer a unique, complete, competent and passionate service.

Sir Luigi Sterchele - Founder

The Sterchele Group Team

In over 60 years of history, Sterchele Group has accomplished remarkable achievements, undertaken major construction projects, and played a vital role in advancing the construction industry not only in Italy but across Europe.

Thanks to all the people who made it possible.

BACK TO MENUPANNELLO 4

1970, il nostro primo negozio:

Sterchele entra nel mercato dei materiali edili e rivestimenti

È l’inizio degli anni ‘70 in Italia e partiamo con una piccola agenzia con deposito nella nostra sede di Isola Vicentina.

Sfoglia la gallery che mostra l’interno del negozio e rivivi la nostra storia.

TORNA AL MENUPANNELLO 5

1984, brevettiamo il Palladium:

Sterchele apripista

Il sistema costruttivo antisismico Palladium è moderno, veloce ed efficace.

Sterchele fa da apripista e brevetta il sistema.

Guarda le foto d’epoca e rivivi quei momenti.

PANNELLO 6

1989, la volta della chiesa di Pero

È il 1989, Sterchele realizza la volta della chiesa di Pero con Travi PREM su carrelli (appoggi) scorrevoli.

Guarda le foto dello storico cantiere.

PANNELLO 8

1997, il cantiere Como Borghi 2000

Il complesso edilizio Como Borghi 2000 è una delle più imponenti volumetrie realizzate nell’ultimo decennio del Novecento nella convalle comasca.

Tre piani interrati di parcheggi, uno di supermercato, sei per residenze e uffici, intorno a due piazze interne.

Il complesso è collegato con la stazione di Como Borghi e il gruppo scolastico di Setificio e Università.

Sfoglia la gallery e guarda il video del cantiere.

PANNELLO 9

1993, il primo stabilimento delle Cellule Bagno Sterchele

La produzione delle cellule bagno inizia in uno stabilimento a Vicenza, in zona Fiera.

La produzione dei telai avveniva nela nostra sede di Cavazzale, il getto ad Isola Vicentina e l’assemblaggio a Vicenza.

Sfoglia la gallery.

TORNA AL MENUPANNELLO 12

2006, si accende la competizione fra le sorelle Sterchele e S.D.

Sfoglia la gallery qui sotto per scoprire le squadre e fare un tuffo nel passato.

Sfoglia la gallery qui sotto.

TORNA AL MENUPANNELLO 14

2019, la NOKIA Arena

Importante centro sportivo e di intrattenimento a Tampere, in Finlandia.

Progettata per ridefinire gli standard architettonici delle sedi sportive, combina funzioni di svago, servizi, residenze e un Hotel Lapland.

Sterchele produce e installa 274 cellule bagno per le camere dell’hotel diversificate in 8 tipologie, con finiture di primo livello ed attrezzate di sauna.

TORNA AL MENUPANNELLO 15

2022, MEMC

La MEMC Electronic Material S.p.A. è il più grande produttore di wafer di silicio di tutta l'UE. L'Azienda sceglie Sterchele Group per l’ampliamento dell’impianto produttivo di Novara, con un nuovo insediamento di 29.000 mq.

Si tratta di uno dei più grandi cantieri realizzati in Italia con il Sistema prefabbricato a Nodo Umido Strutturale; un progetto sfidante, per il quale abbiamo messo in campo tutta la nostra esperienza elaborando soluzioni innovative, funzionali alle esigenze progettuali.

TORNA AL MENUPANNELLO 16

Il team di Sterchele Group

In questi oltre 60 anni di storia Sterchele Group ha collezionato risultati fuori dal comune, realizzato cantieri importanti e partecipato allo sviluppo dell’edilizia non solo italiana ma anche europea.

Grazie a tutte le persone che l’hanno reso possibile.

TORNA AL MENU